How do glass and ceramic jar manufacturers overcome the challenge of fragile glass during transport? Cupwind's Four-Layer Protection System

Imagine: A container arrives at your warehouse after 30 days of sea freight, weathering storms and port handling. The moment the container door opens, you are greeted by neatly arranged, perfectly preserved custom-made frosted glass candle jars, each one intact. This moment of peace of mind is not accidental, but the inevitable result of a sophisticated protection system.

For international buyers, the journey of a product is as important as its manufacturing quality. At Cupwind, we understand that reputation is built not only on the exquisite craftsmanship of glassware, but also on the ability to deliver it flawlessly.

First Layer of Protection: Microscopic Air Cushioning

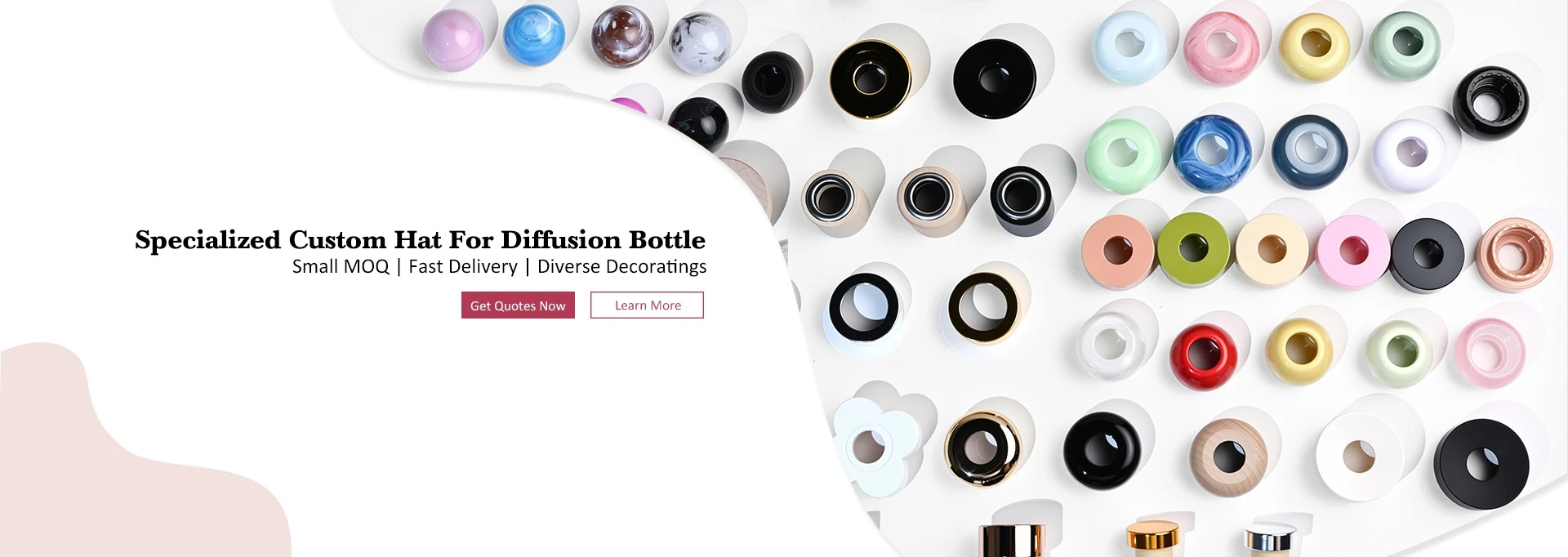

Every product—whether it's a low-minimum-order crystal wine glass, a bulk purchase of colored diffusers, or a custom-designed logo frosted candle jar—has a 50-micron OPP bag as its first line of defense. A 3mm air cushion layer, formed through heat-sealing technology, absorbs the initial 4G impact before the packaging box even detects it, preventing microscopic stress damage at its source.

Custom logo frosted glass candle jars factory

Second Layer of Protection: Honeycomb Matrix Partitioning

We use custom-made honeycomb partitioned cartons, with each compartment precisely cut 2mm larger than the product, forming a tight, friction-free package. Using ECT 38 lb/sq ft three-layer corrugated cardboard, this internal grid structure transforms ordinary cartons into a rigid, shock-absorbing matrix, ensuring zero contact with glass surfaces during transport.

Third Layer of Protection: Wooden Pallet Armor

We insist on using ISPM-15 standard pine pallets (12×1.5cm), combined with 200 gauge industrial stretch film, forming a uniform and stable loading unit. Real-world testing data shows that vibration transmission is reduced by 40% compared to plastic pallets, effectively coping with the bumps and jolts of land transport.

Low price colored diffuser glass bulk order

Fourth Layer of Protection: Container Safety Net

In the final stage of packing, we install a 450daN strength polypropylene safety net at the container door. This "safety buckle," which takes only 30 seconds to install, prevents the risk of cargo collapse when the door is opened, mitigating a potential loss of $1200 at a cost of only $3.

This protective system applies to all orders—from small orders of 300 custom frosted glass pieces to large-scale purchases of entire containers of colored diffuser glass. Through efficiency improvements such as heat recovery in our production processes, we invest cost savings into higher-quality packaging materials, ensuring low prices without compromising quality.

Low MOQ crystal wine glassware factory

As a buyer, the true cost of a product includes the risk of its safe arrival. At Cupwind, we reduce this risk to zero with four layers of protection. We not only manufacture exquisite glass and ceramic jars, but also ensure their perfect journey across 12,000 nautical miles.

Do you have similar concerns about the fragility of glass products during transport? Share your experiences, and we will provide robust packaging protection for your purchased products.